EN | DE

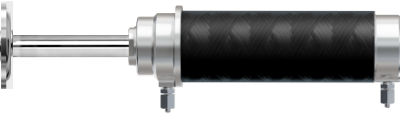

Our ultra-light hydraulic cylinders are

up to

70 Percent

lighter

than comparable cylinders available on the market.

Mark LIGHT...

… has been part of the MARK Group since 2008 and is expanding its product portfolio to include a completely new division: extremely lightweight, compact and powerful carbon hybrid cylinders.

The MARK Group can look back on over 105 years of experience and currently employs around 550 people. Every year, it supplies more than three billion high-precision small parts of consistently high quality – with zero-defect tolerance – all over the world.

Thanks to the close connection to the automotive-focussed MARK Group, the quality and safety of our cylinders have been our top priority from the very beginning.

Our vision is...

… to create a completely new product by combining innovative carbon winding technology with proven hydraulic cylinder technology – with a wide range of options for increasing efficiency in hydraulic systems. True to the motto: No more oversized, heavy hydraulic cylinders – instead, lightweight, high-strength and optimally customised solutions for maximum performance!

Thanks to consistent investment in research and development, a tireless team and the support of a strong group of companies, a ground-breaking product was finally created: the MARK Carbon Hybrid Cylinder.

Today, this vision is already a reality – we supply thousands of cylinders every year. But this is just the beginning. Let us surprise you with what the future has in store!

Our dachshund is...

… in our logo for good reason! When Rudolf MARK Senior founded the MARK company in 1920, he was completely on his own and had to ensure that the machines ran around the clock.

But sometimes, usually late at night, the hard-working founder would fall asleep from exhaustion. This is exactly where his faithful dachshund came into play! He was exceptionally intelligent and could hear if there was any deviation in the production process.

As soon as this happened, the dachshund started barking and woke its owner – who was then able to intervene immediately. Out of gratitude and as a sign of his loyalty, Rudolf MARK Senior immortalised the dog in the company logo.

This made our dachshund not only the first employee, but also the first sensor in the history of MARK!

KEVIN BRAUN

Sales

Powerful

Energy efficiency that pays off easily

- Lifting platform – Load moment

- Transport industry – deadweight

- Agricultural technology – load moment, corrosion

- Maritime – weight, corrosion

- Microcylinders – exoskeletons, tools

- E-mobility – weight reduction

- Rescue cylinders – fire brigade, police

ALFRED KINDL

Head of Project Management

Lightweight

The carbon cylinder from ALKO shown here weighs 3.2 kg. A conventional steel cylinder weighs 6.8 kg.

What does carbon hybrid mean?

A MARK carbon hybrid cylinder combines the best of two worlds: Classic, high-strength metal materials such as aluminium or steel are combined with lightweight but extremely high-performance carbon fibres (CFRP). Carbon fibre takes on the role of a structural connecting element.

Your advantages at a glance

Individual customisation – without long development times

Minimal weight – thanks to optimum material mix

Highest quality & reliability – thanks to tried and tested components Cost-efficient & fast – thanks to modular production

Two designs for different requirements

Serviceable cylinders – dismountable & easy to maintain

Ideal for applications that require regular maintenance. These cylinders are easy to dismantle and maintain.

Maintenance-free cylinders – durable & efficient

Perfectly matched to the service life of your application – without oversizing and without maintenance effort!

These cylinders are designed to operate reliably and maintenance-free for their entire service life – without the need for disassembly or servicing.

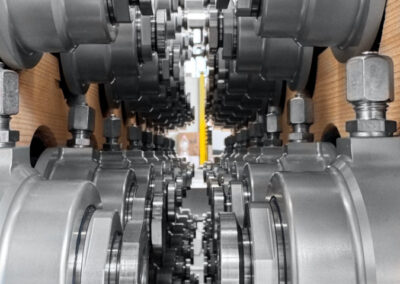

Proven materials

Precision-manufactured components such as pistons, rod guides and cylinder bases are made of aluminium or steel – for maximum resilience and durability. Depending on the application, coated steel piston tubes are usually used.

Liner

The inner tube, the liner, is extremely thin-walled – just 0.4 mm for microcylinders, for example – and ensures optimum tightness and precise sealing clearance.

Carbon

As a rule, all cylinder parts are fully assembled and then wrapped in carbon fibre. Only this carbon sheathing connects the end parts, such as the rod guide and cylinder base, and thus guarantees the optimum function of the cylinder. The carbon takes on the role of a structural connecting element – without any welding, gluing or threading.

Optimum lightweight solution and modular design

Instead of developing each cylinder from scratch, we rely on tried and tested proven modules. This results in customised carbon hybrid cylinders that are perfectly tailored to your requirements..

Alfred – My conclusion:

We know our materials down to the last detail and know exactly how to use them efficiently to get the best out of them. Thanks to our experience and innovative technology, you get a lightweight, durable and powerful hydraulic cylinder that is perfectly matched to your application.

Why use lightweight carbon hybrid cylinders?

Operation

- Increased efficiency – shorter cycle time – lower mass acceleration and deceleration

- Greater sustainability – fewer CO₂ emissions during operation

- Higher payload – more load capacity due to weight saving

- Soil protection – lower ground pressure

- Weight load per m² – small construction machinery in buildings

- Less wear – preservation of tribological properties

- Lower fuel consumption – less mass, less energy required

- Corrosion resistance – carbon is not susceptible to rust or chemicals.

Construction

- Simpler overall design – Optimised dimensioning of machine parts

- Permissible axle loads – Compliance with weight restrictions

- More flexible designs – Longer booms possible

- Stability – Reduction of the tipping load

Assembly/Service

- Faster installation – Easier handling reduces installation time

Optimised lightweight construction

Customised to the application – for maximum efficiency and durability.

Your advantage

- Customised design – Perfectly matched to load cycles, operating conditions & reserve

- Material reduction – Only the essentials for low weight & high performance

- High-tech materials – Carbon, aluminium & high-performance steels for optimum strength

- Durability & reserve – Safe operation based on the load spectrum for maximum reliability

- Increased efficiency – Less weight saves energy, ideal for mobile applications

Why Carbon

- High strength – CFRP is extremely resistant to tension and compression, ideal for load-bearing structures

- High rigidity – High modulus of elasticity, advantageous for dynamic loads

- Low density – Significantly lighter than steel or aluminium, saves weight and energy

- Corrosion resistance – Rust-free and resistant to many chemicals

- Good damping behaviour – Effectively reduces vibrations and oscillations

- Fatigue resistance – Stable despite repeated loads, less material fatigue

- X-ray transparency – Permeable to X-rays, ideal for medical technology & aviation

- Customisable properties – Fibre orientation & resin matrix can be precisely matched to the application

- Adjustable thermal expansion – Minimised thermal expansion for precise components

Example: 100,000 load cycles

- Analyse load profile and design precisely for 100,000 cycles

- Select optimally matched materials (e.g. carbon sheath, aluminium internal components)

- Allow for a sufficient safety margin – not oversized, but precisely optimised for the required service life

Kevin – My conclusion:

Our aim was not only to develop lightweight cylinders, but also to manufacture them quickly and easily – and that’s exactly what our modular design makes possible. The precise coordination of all components results in a particularly light, powerful and durable carbon hybrid cylinder in the shortest possible time.

cylinder – for maximum efficiency with minimum material usage.

Production

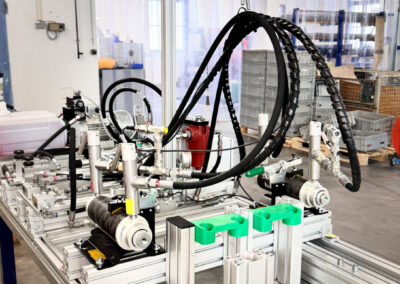

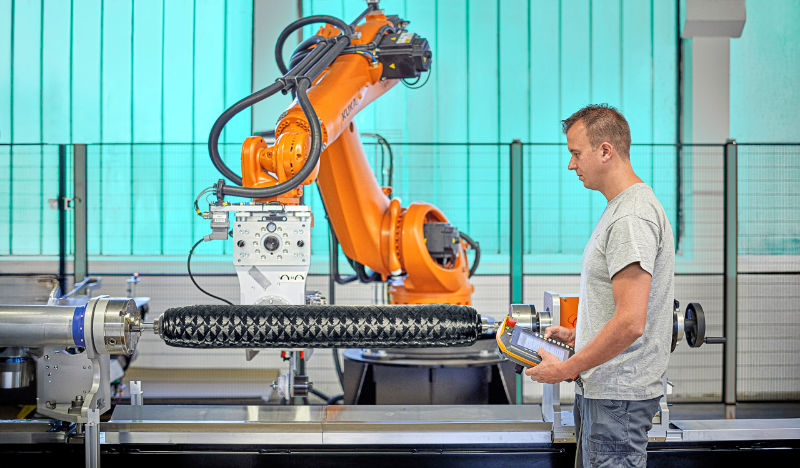

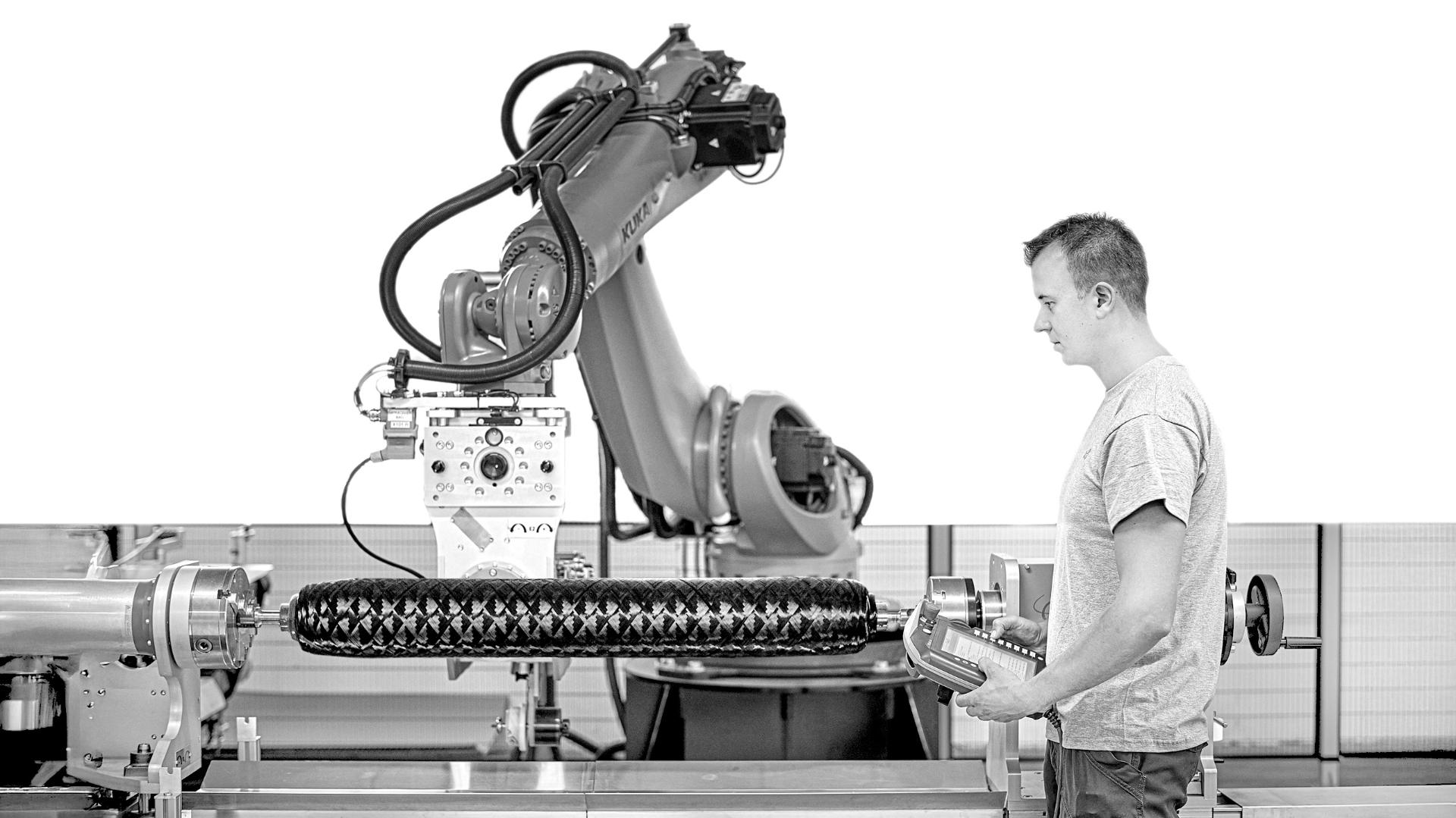

Carbon wet winding process

In wet winding, the carbon fibres are impregnated with resin directly during the winding process before they are applied to the core or mould. This process enables particularly even resin distribution and high fibre penetration, which optimises the mechanical properties of the component. The winding structure is based on years of experience and precise, computer-aided analyses. It is optimised using special software and then produced fully automatically. After curing in the oven, the cylinder is ready for use.

Quality management and testing

Thanks to the automotive supplier expertise of the Mark Group (>500 employees), we work to the highest quality standards and are ISO 9001 certified.

We have been developing, manufacturing and testing lightweight hydraulic cylinders since 2008 – on test benches and in real-life applications. Some have completed over 7 million cycles, one of which has been working reliably on a snow plough in Spital am Pyhrn since 2012.

Development test bench

We can test and inspect cylinders of various designs under programme-controlled loads on our 8 metre long test bench.

Test bench characteristics:

- Pressure up to 550 bar

- Back pressure (piston and rod side)

- Buckling test

- Cold test

- Cycles

- Stroke

- Piston speed

- Recording

- Archiving

- Evaluation

Test bench delivery

100 % cylinder testing

Each cylinder is subjected to a comprehensive test and, depending on

with or without oil, depending on customer requirements.

Customised tests

Special customer requirements are specifically tested on our test benches. In the video we show a transverse load test with a 200 kg weight. The cylinder was loaded over thousands of cycles.

Areas of application

Transport industry

Particularly lightweight and economical hydraulic cylinders for the transport industry

For our customers in the transport sector, we have developed a special cylinder for securing loads during transport. Thanks to our innovative material savings, we were able to reduce the weight of the cylinder from almost 12 kg to just 5.5 kg.

As the customer has integrated several of these cylinders into his system, the weight saving now finally enables a full payload without exceeding the maximum permissible total weight. Lighter, more efficient, more economical!

Caravan levelling cylinder

Customer example AL-KO

An innovative telescopic cylinder was developed for AL-KO Fahrzeugtechnik that enables a greater stroke despite the same installation length. At the same time, the weight has been drastically reduced – from 6.8 kg to just 3.2 kg. Small, compact and light!

To ensure the highest quality and durability, the cylinders were subjected to intensive testing – on test benches, in climatic chambers, on the hydropulser, on test tracks and in the real world. They had to reliably withstand lateral loads of 200 kg over half the cylinder’s service life.

This shows just how powerful our carbon hybrid cylinders really are! They combine maximum load capacity with minimum weight and set new standards in caravan levelling technology.

Ambulance transport

Particularly lightweight, high-strength and safe hydraulic cylinders for patient transport

We have developed small, lightweight and compact cylinders for use in rescue stretchers especially for our customers in the medical and rescue technology sector. Targeted optimisations have enabled us to reduce the weight from 4.7 kg to just 1.6 kg!

Every kilogram counts, especially when carrying patients in narrow stairwells – this is where our cylinder makes the decisive difference!

As the safety requirements in this sector are particularly high, the cylinders were tested to extremely high safety standards. Finally, a burst test was carried out in which the cylinder was subjected to a pressure of 600 bar three times for one minute – without sustaining any damage!

Agricultural industry

Particularly lightweight and chemical corrosion-resistant hydraulic cylinders for the agricultural industry

We have developed particularly chemical-resistant carbon hybrid cylinders for our customers in the agricultural industry, especially manufacturers of field sprayers and pneumatic spreaders.

Carbon itself is absolutely insensitive to chemicals and corrosion. The aluminium add-on parts are anodised and additionally painted to ensure maximum resistance.

We have also achieved impressive weight savings in this area: For cylinders with piston diameters of 40-60 mm, the weight has been reduced by over 50%! This means lighter booms, larger working widths and even more efficient machines!

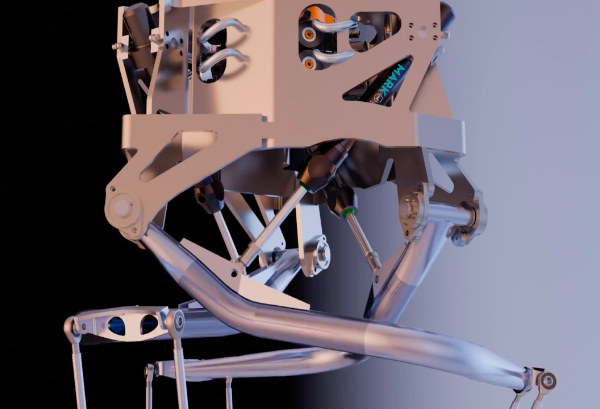

Robotics

Our lightweight carbon hybrid cylinders enable precise, fast control in robotics applications. They ensure high acceleration, exact stops and efficient motion sequences – ideal for modern, automated systems.

Fire brigade and police

Particularly light and compact rescue rams for fire brigades and police forces

Weight reduction plays a particularly important role here – because the lighter the cylinder, the less force a person has to exert.

With our lightweight cylinders, the fire brigade can free a casualty from a vehicle more quickly or fire and police emergency services can open flat doors more easily.

Our customers need compact, lightweight cylinders that can withstand extreme loads. We supply a special cylinder series designed for 365 bar operating pressure. However, our latest development clearly exceeds this value – these cylinders are approved for up to 500 bar and set new standards in rescue technology!

MARK HYDRAULIK GMBH

Gleinkerau 23, 4582 Spital am Pyhrn

AUSTRIA

+43 7563 8002 0

carbon@mark-light.com

+43 7563 8041 0

Jobs at Mark Light

“Currently none – please check back again!”